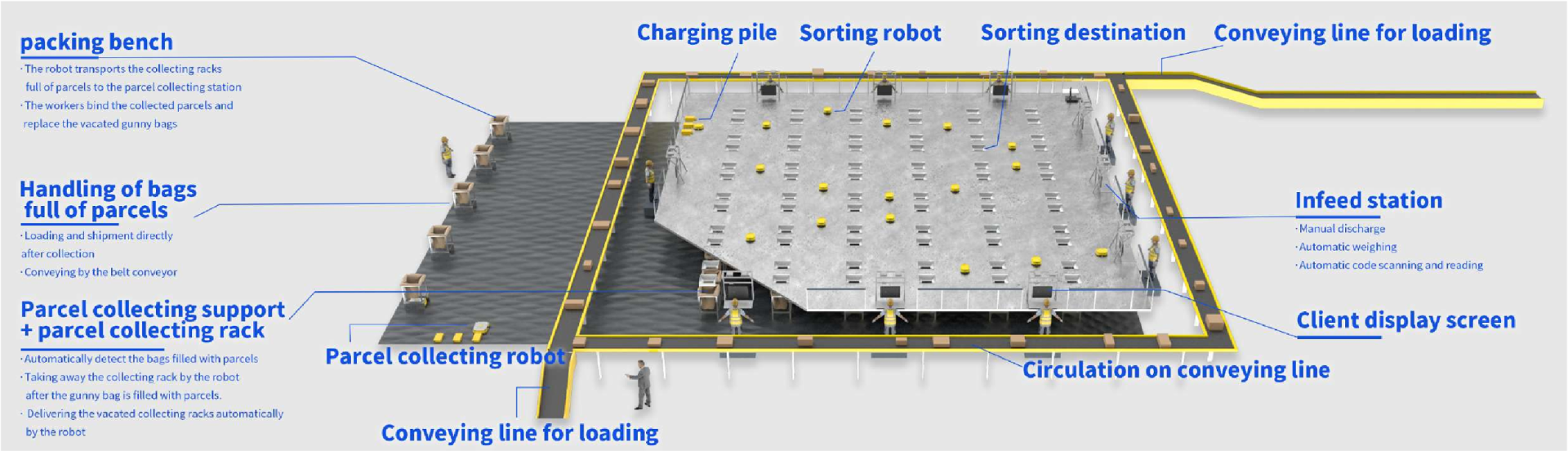

Steel Platform Sorting System

Specification of standard system (*for reference only)

- Capacity per hour : 20000 pcs

- Floor area : 1300 m²

- Number of robots : 350 pcs

- Number of in feed stations : 18

- Number of destinations : 240

- Error rate < 0,01 %

- System power consumption < 8Kw

- Labor saved > 60 %

Overview

The steel platform sorting system is composed of steel platform (Fixed system), robot sorting system (core system), package collecting system, and conveying system. The system is highly flexible, allowing you to add or remove robots as appropriate. It deploys faster and requires fewer robots, which provides a perfect solution for massive sorting projects, such as courier and e-commerce industry.

ADVANTAGES

-

Highly productive & efficient

- 350 robots, capable of sorting over 20,000 parcels per hour

- Continuous operation for 24 hours, capable of handling over 400,000 parcels

- Improved sorting efficiency with AI algorithm, 2-3 faster than human

- Add more robots during peak season for higher efficiency in short term

-

Flexible working pattern

- The system calculates the optimal path for hundreds of robots to work in synergy

- Visualized management allows you to monitor the robot’s operation in real time

-

Space saving

- It takes up less than half the space compared with other systems, effectively saving cost on space

- In regular case, an area of about 1300m² can accommodate up to 240 grid, making full use of the space

-

Stable & accurate

- The fault tolerant system ensures smooth operation of entire system despite failure in on robot

- The sorting system is stable with an accuracy more than 99,99% as long as the input is right

-

Quick deployment & easy maintenance

- It takes only 1-2 months to build the system from scratch

- Not only space and time efficient, the system is also easy to operate and maintain

-

Manual sorting replaced by robots

- Automatically locate the right grid for delivery through barcode on the parcel

- Automatic feeding, reading, weighing, sorting, and collecting helps save up to 60% of labor cost

-

High ROI

- Flexible capital investment, short investment cycle, waste no time before into motion, low expantion cost, high space and labor efficiency

- Cost much less compared with heavy-duty automation equipment, and also with traditional manual and cross belt sorting modes from the perspective of 3-5 year investment

WHY WIN - SORT

Small unit with many application and solution.

- Steel platform is a fixed system, consisting of upper and lower layers

- Sorting robot

- Computer control system

- Network system

- Scanning and weighing equipment

- Air bag (optional)

- Available space check

- Collecting robot

- Collecting rack, packing bench

- Feed conveying line

- Discharge conveying line

- All kinds of belt conveyore or conveying machine, sealing-tape machine, track system

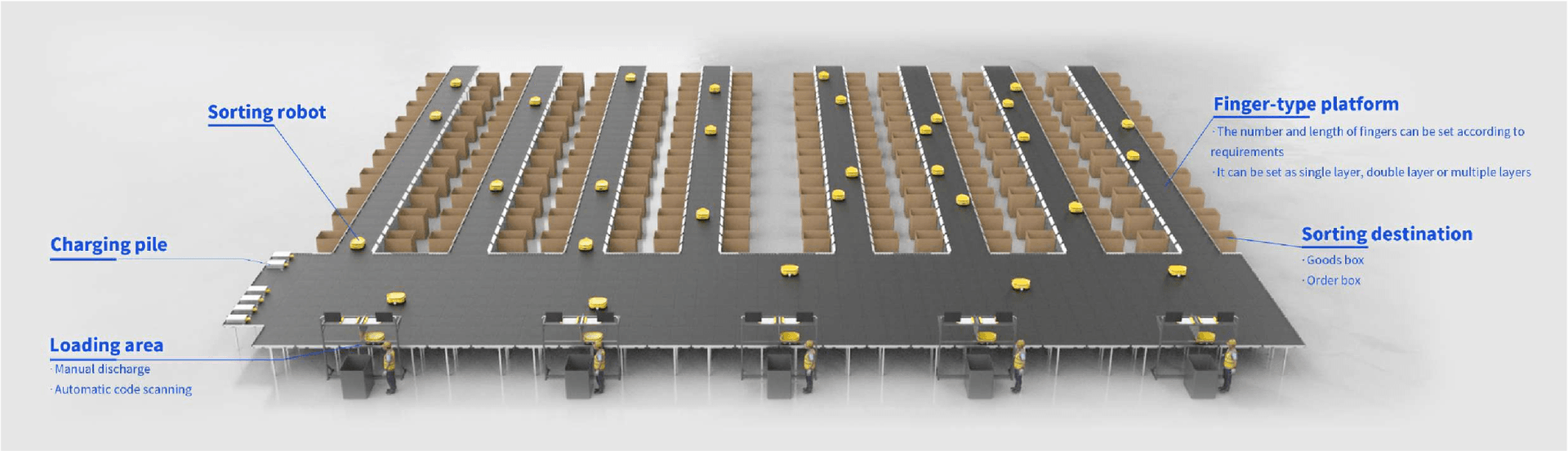

Table Platform sorting system

We have developed a highly flexible table platform sorting system tailored for operations such as order picking. The system is flexible so you can add or reduce table platform, robots, and adjust the number of sorting grids as needed. It is designed for batch order picking, stock replenishment (by store), and return processing (by SKU sorting), and suited for forward sorting and reverse sorting in courier, retail, supermarket, and clothing industries.

ADVANTAGES

-

Highly productive & efficient

- The modular system makes for high expansibility, rapid deployment and phased deployment

- The system is flexible so that you can add or remove robots as needed

-

Intelligent and efficient

- Computer controlled operations, automatic code scanning, intelligent identification, fast transfer, and precise delivery

- System chooses optimal sorting paths from multiple options to improve the efficiency of robot sorting

-

Wide application and easy deployment

- The system is suitable for various industries and multiple scenarios

- Not limited by space, can be deployed on the ground, desk top, and in the air

- In the best case scenario, it only takes 2-3 weeks to set up

-

Stable & accurate

- The fault tolerant system ensures smooth operation of entire system despite failure in on robot

- The sorting system is stable with an accuracy more than 99,99% as long as the input is right

-

High ROI

- Start up at lower cost, with the option to gradually invest more as the project grows

- Project cycle is sort and return on investment is high. The payback period is generally less than 3 years with the retuen rate is estimated to be more than doubled

-

More intuitive with visual management

- Robot operation is monitored in real time

- Robot condition is displayed on the screen for efficient maintenance

WHY WIN - SORT

Small unit with many application and solution.

- Patched together with table or rack on hand

- Customized platform with galvanized steel

- Sorting robot

- Computer control system

- Network system

- Scanning and weighing equipment

- All kind of conveyior system