Steel Platform Sorting System

Specification of standard system (*for reference only)

- Capacity per hour : 20000 pcs

- Floor area : 1300 m²

- Number of robots : 350 pcs

- Number of in feed stations : 18

- Number of destinations : 240

- Error rate < 0,01 %

- System power consumption < 8Kw

- Labor saved > 60 %

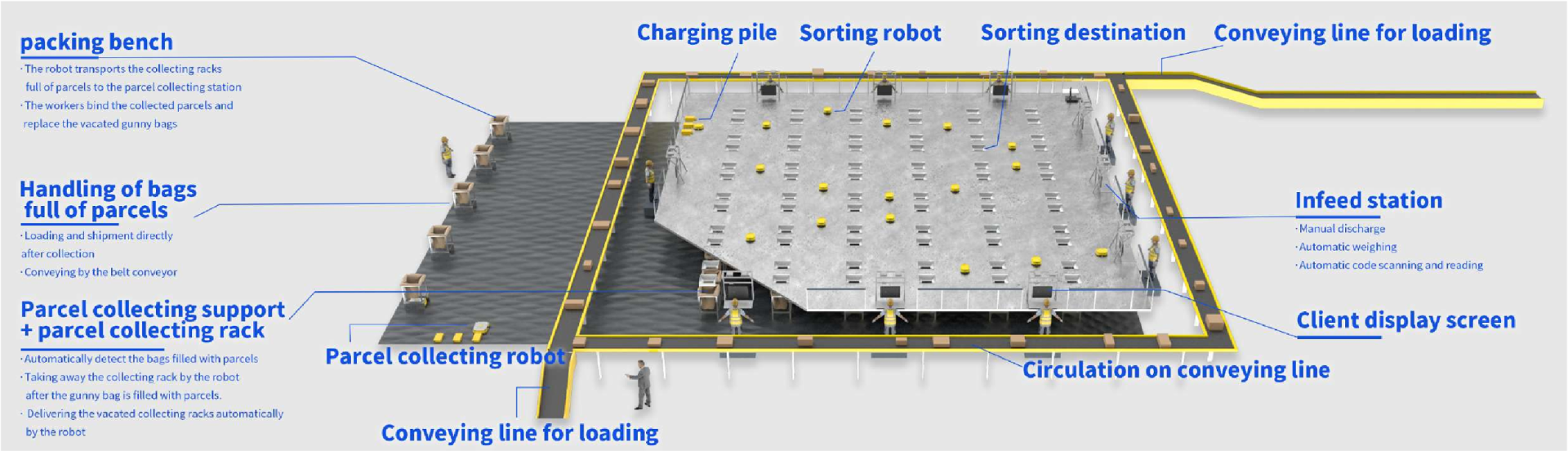

Overview

The steel platform sorting system is composed of steel platform (Fixed system), robot sorting system (core system), package collecting system, and conveying system. The system is highly flexible, allowing you to add or remove robots as appropriate. It deploys faster and requires fewer robots, which provides a perfect solution for massive sorting projects, such as courier and e-commerce industry.

ADVANTAGES

WHY WIN - SORT

Small unit with many application and solution.

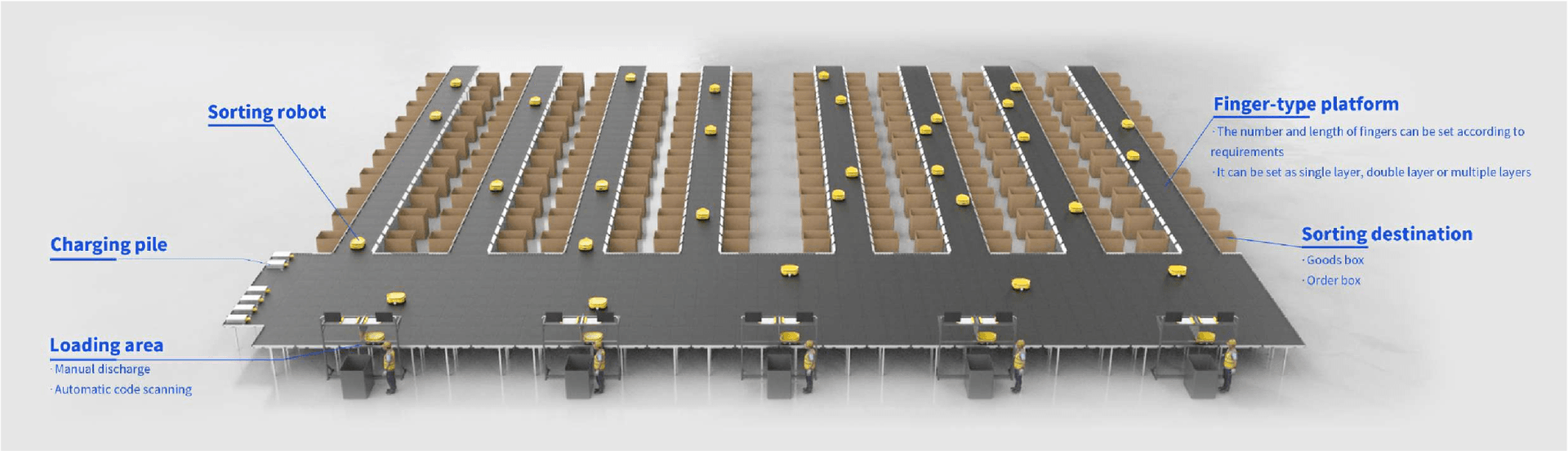

Table Platform sorting system

We have developed a highly flexible table platform sorting system tailored for operations such as order picking. The system is flexible so you can add or reduce table platform, robots, and adjust the number of sorting grids as needed. It is designed for batch order picking, stock replenishment (by store), and return processing (by SKU sorting), and suited for forward sorting and reverse sorting in courier, retail, supermarket, and clothing industries.

ADVANTAGES

WHY WIN - SORT